Waterproofing is a critical aspect of construction, particularly in projects where water infiltration can undermine structural integrity, such as tunnels, basements, and retaining walls. To effectively seal concrete joints and prevent water seepage, GFRP (Glass Fiber Reinforced Polymer) Water Stop Screws have emerged as a cutting-edge solution. These non-metallic fasteners offer several advantages over traditional metal options, providing long-term durability, enhanced corrosion resistance, and easy installation.

In this article, we will explore how to choose the right GFRP Water Stop Screws for your construction project. From understanding their material composition to key selection criteria, installation considerations, and lifecycle management, this guide will help ensure that your project benefits from efficient and effective water sealing.

1. The Importance of Water Sealing in Construction

What is Water Sealing and Why is it Critical?

Water sealing refers to the process of preventing the ingress of water into a structure, typically by sealing joints, cracks, or gaps between different parts of the construction. In buildings, tunnels, and underground structures, water infiltration can lead to structural damage, erosion, mold growth, and compromised safety.

Waterproofing is especially crucial in foundations, basements, tunnels, and water treatment plants where exposure to moisture is constant. As these environments are subject to high water pressure, selecting the right water-stop solution is essential for long-term durability.

The Role of Water Stop Screws in Waterproofing

Water stop screws are commonly used in construction to prevent water from entering through the gaps between joints in concrete structures. These screws anchor into concrete to form a tight seal, ensuring that water cannot seep through. Traditionally, metal screws were used, but the shift toward GFRP Water Stop Screws is a response to their superior performance, especially in harsh environments.

2. Understanding GFRP Water Stop Screws

What Are GFRP Water Stop Screws?

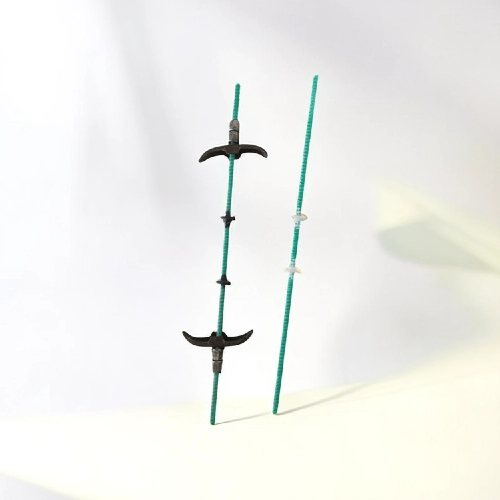

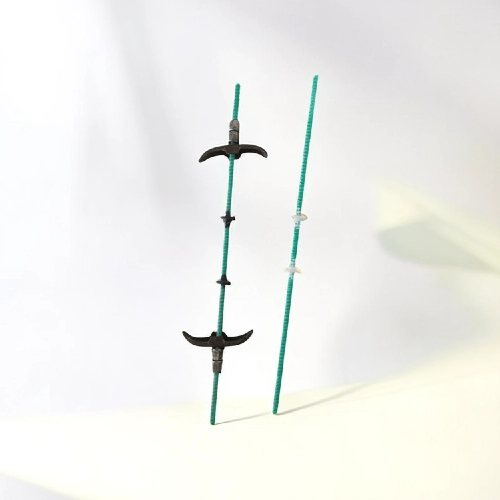

GFRP Water Stop Screws are fasteners made from glass fiber reinforced polymer. They combine glass fibers with a polymer resin to create a lightweight, strong, and corrosion-resistant screw that is ideal for water sealing in concrete joints. Unlike traditional metal screws, GFRP screws are non-conductive and resistant to corrosion, making them suitable for wet and chemically aggressive environments.

These screws are inserted into pre-drilled holes in concrete formwork, and their design allows them to tightly seal the joints, preventing water from entering through the cracks.

Material Composition and Properties

The core material of GFRP Water Stop Screws is composed of glass fibers and polymer resins such as epoxy or vinyl ester. Glass fibers provide tensile strength, while the resin binds the fibers and offers additional chemical resistance. Key properties include:

Corrosion Resistance: Unlike metal, GFRP screws do not rust or degrade over time, even in damp or saline conditions.

Lightweight Design: GFRP is significantly lighter than metal, making the installation process easier and reducing labor costs.

High Strength: Despite their lightweight design, GFRP screws maintain high tensile strength and can withstand the forces exerted by water pressure.

Chemical Resistance: GFRP is resistant to a variety of chemicals, making it ideal for applications in industrial and water treatment settings.

How GFRP Water Stop Screws Work

GFRP Water Stop Screws are designed to be installed at the junctions of concrete joints, where they create a water-tight seal. The screws are inserted into the concrete and secured by grouting, forming an impermeable barrier that stops water from penetrating. These screws are particularly useful in environments where steel or iron would corrode over time.

3. Key Selection Criteria for GFRP Water Stop Screws

Choosing the right GFRP Water Stop Screw involves considering several factors to ensure they meet the needs of your construction project. These include environmental conditions, mechanical performance, installation ease, and long-term durability.

3.1. Environmental and Site Conditions

When selecting GFRP Water Stop Screws, it’s important to assess the environmental conditions of your project site:

Water Exposure: GFRP screws are ideal for areas exposed to high moisture, such as basements, tunnels, or water treatment facilities.

Chemical Exposure: In environments where concrete will be exposed to chemicals, GFRP’s chemical resistance ensures long-term integrity.

Temperature Extremes: GFRP materials can withstand a wide range of temperatures, making them suitable for both hot and cold environments.

3.2. Mechanical and Sealing Performance

The mechanical performance of GFRP Water Stop Screws is essential in ensuring that they provide a strong seal under water pressure. The following factors should be considered:

Required Diameter and Length: The diameter and length of the screw will vary depending on the size of the concrete joint and the water pressure expected.

Water-Stopping Pressure: Choose screws based on their ability to withstand the water pressure in the specific environment. This will ensure they perform effectively under extreme conditions.

3.3. Installation Considerations

While GFRP Water Stop Screws are easier to install than traditional metal screws, the following factors should still be considered:

Ease of Installation: Due to their lightweight nature, GFRP screws are easier to handle, reducing installation time and labor costs.

Compatibility with Formwork: Ensure the screws are compatible with the type of formwork used in your construction project to facilitate smooth installation.

3.4. Lifecycle and Maintenance Implications

GFRP Water Stop Screws offer long-term benefits when it comes to maintenance:

Durability: GFRP’s resistance to corrosion ensures that the screws will not degrade over time, reducing the need for frequent repairs or replacements.

Low Maintenance: These screws require minimal maintenance compared to metal alternatives, leading to cost savings over the project’s lifespan.

4. Comparative Table: GFRP Water Stop Screws vs Traditional Metal Water Stop Screws

Here is a comparison between GFRP Water Stop Screws and traditional metal water stop screws:

Criteria | GFRP Water Stop Screws | Traditional Metal Water Stop Screws |

Material Composition | Glass fiber reinforced polymer (non metallic) | Steel, iron, or aluminum (metallic) |

Corrosion Resistance | High resistance to rust and corrosion | Prone to rust in damp or saline environments |

Weight | Lightweight, easy to handle | Heavy and difficult to transport |

Chemical Resistance | Excellent resistance to various chemicals | Limited resistance to chemicals, prone to degradation |

Installation | Easier and faster installation | Heavier, more labor intensive installation |

Maintenance | Very low maintenance, long term durability | Requires frequent maintenance and inspection due to corrosion |

Service Life | Long service life due to corrosion resistance | Shorter service life in aggressive environments |

Key Differences in Performance

Corrosion Resistance: GFRP Water Stop Screws excel in corrosive environments, whereas metal screws are prone to rust, especially in high-moisture or chemical-exposed conditions.

Weight and Handling: The lightweight nature of GFRP Water Stop Screws reduces transportation and installation costs, whereas traditional metal screws require more effort to transport and handle.

Longevity: GFRP’s durability reduces the need for replacements, making them a more cost-effective option in the long run.

5. Best Practices for Choosing the Right GFRP Water Stop Screw

Match Specifications to Project Requirements

It is essential to match the GFRP Water Stop Screw specifications to the requirements of your project. This includes selecting the appropriate diameter, length, and thread type based on the concrete joint size, expected water pressure, and sealing needs.

Check Manufacturer's Quality Assurance

Ensure that the GFRP Water Stop Screws come from a reputable manufacturer who provides certification for the product. Look for performance data such as water-sealing pressure, material resistance to chemicals, and longevity tests.

Plan for Installation Logistics

Proper installation is crucial for ensuring an effective seal. Make sure to assess site conditions, including the ease of access, required tools, and labor needed for installing GFRP Water Stop Screws.

Consider Total Cost of Ownership

While GFRP Water Stop Screws may have a higher initial cost, their durability and minimal maintenance requirements make them more cost-effective over the long run.

6. Conclusion

In conclusion, GFRP Water Stop Screws are an ideal solution for achieving efficient and durable water sealing in concrete structures. Their excellent corrosion resistance, lightweight design, and minimal maintenance make them perfect for use in environments exposed to moisture, chemicals, or high-pressure conditions. By carefully considering the selection criteria discussed in this article, you can ensure the right GFRP Water Stop Screws are chosen for your project, helping to achieve long-term, reliable performance.

At JIMEI CHEMICAL Co., Ltd., we specialize in providing high-quality GFRP Water Stop Screws tailored to meet the specific needs of your construction projects. Our solutions are designed to offer superior durability, ease of installation, and long-lasting water sealing. We invite you to contact us for more information on how our products can enhance your next project, ensuring it meets the highest standards of performance and efficiency. Let us help you achieve optimal water sealing with our advanced GFRP solutions.

7. FAQ

What are GFRP Water Stop Screws?

GFRP Water Stop Screws are non-metallic fasteners made from glass fiber reinforced polymer. They are designed to create a water-tight seal in concrete joints to prevent water ingress.

How do GFRP Water Stop Screws differ from traditional metal screws?

GFRP Water Stop Screws offer superior corrosion resistance, lighter weight, and require less maintenance compared to traditional metal screws, making them ideal for harsh environments.

What factors should I consider when selecting GFRP Water Stop Screws?

Consider environmental conditions (moisture, chemicals, temperature), mechanical performance (sealing pressure, diameter), and ease of installation when selecting the right screws for your project.

Are GFRP Water Stop Screws more expensive than metal options?

While GFRP Water Stop Screws may have a higher initial cost, their durability, corrosion resistance, and low maintenance requirements make them more cost-effective in the long term.

Can GFRP Water Stop Screws be used in all construction types?

Yes, GFRP Water Stop Screws are suitable for use in various construction environments, particularly where moisture, chemical exposure, or corrosive conditions are a concern.

How long do GFRP Water Stop Screws last?

Due to their corrosion resistance, GFRP Water Stop Screws have a much longer lifespan than metal screws, requiring fewer replacements and maintenance.

How do I install GFRP Water Stop Screws?

GFRP Water Stop Screws are installed by drilling holes into the concrete, inserting the screws, and securing them with grout to form a tight, water-resistant seal.