Anhui Sende FM certified FRP reinforcement: redefining the new benchmark for engineering materials with fire safety standards

FM certification - the 'gold standard' for global fire safety

In the field of building safety, fire risk has always been the 'sword of Damocles' hanging over engineers' heads. As a globally authoritative fire safety certification body, FM Global certification in the United States is regarded as the "safety bottom line" by the North American insurance industry, high-end commercial real estate, and industrial facilities based on its standards. The FM certified FRP reinforcement (fiber-reinforced composite reinforcement) launched by Anhui Sende New Material Technology Development Co., Ltd. is based on this fire safety benchmark, providing a "fire immunity" solution for high-risk scenarios such as tunnels, subway stations, and chemical parks. This article will deeply analyze the core advantages of this product from three dimensions that users are most concerned about: fire performance, engineering safety, and full lifecycle value.

1、 The rigorous test behind FM certification: the "alchemy" of fire safety

FM certification is not simply a 'compliance proof', but a systematic testing of materials through simulating real fire scenarios. During the FM certification process, Sende FRP reinforcement must pass the following key tests:

1. Flame spread suppression: a leap from "combustion" to "self extinguishing"

Test standard: FM 4880 "Standard for Non metallic Cable Trays and Supports Exposed to External Fire" requires materials to not burn or spread in flames for 30 minutes.

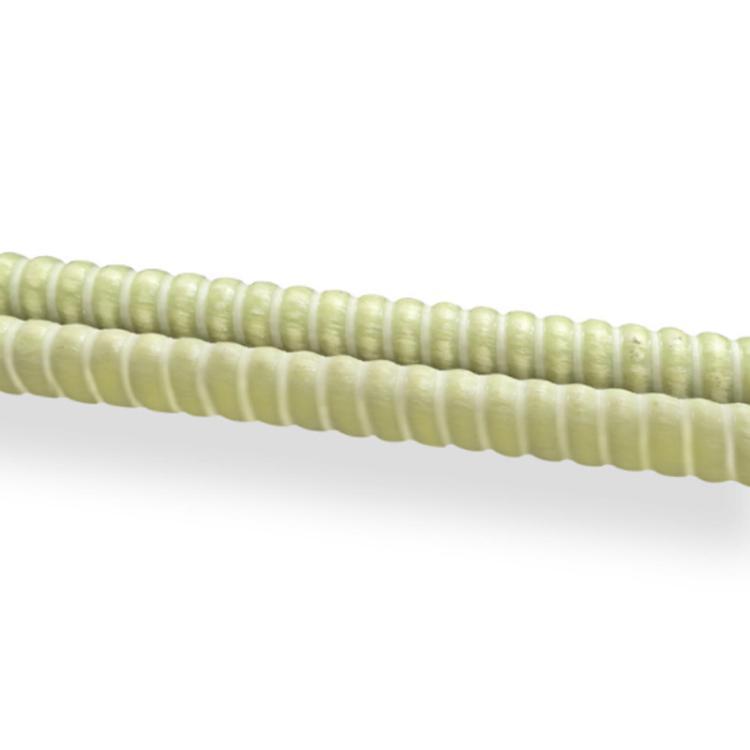

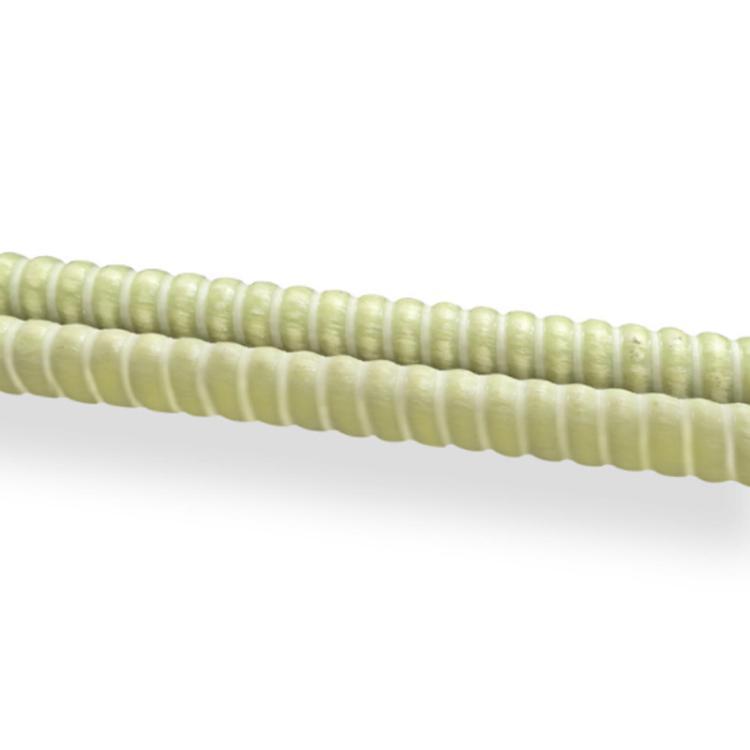

Sende Solution: Using flame-retardant vinyl ester resin matrix and alkali free glass fiber composite, tested by FM certified laboratory, the carbonization layer thickness on the material surface is only 2mm under direct flame impact, without open flame spread, far exceeding the fire resistance of traditional FRP reinforcement.

2. Smoke toxicity control: a breakthrough from "lethal" to "evacuable"

Test standard: FM 4950 "Fire Protection Test for Cleanroom Materials" requires that the smoke density during material combustion be below 15%, and the release of toxic gases (such as CO and HCN) be below the safety threshold.

Sende Solution: Adding nano grade aluminum hydroxide flame retardant to reduce the density of combustion smoke to 12%, with a CO release rate of only 0.03%, meeting international safety escape standards.

3. Fire resistance limit: upgrading from "short-term support" to "long-term defense"

Test standard: ASTM E119 "Fire resistance test for building components" requires materials to maintain structural integrity at a high temperature of 1200 ℃ for at least 2 hours.

Sende Solution: Through multi-layer composite structure design and high-temperature curing process, the fire resistance limit of the product can reach 3 hours, far exceeding the fire resistance time of traditional steel bars.

User Value: FM certification means that the product has passed the world's most rigorous fire safety "stress test", significantly reducing fire risks, minimizing casualties and property damage.

2、 Product Features: A Revolution from Material Innovation to Engineering Safety

Fiberglass Reinforcement: Reshaping the Future of Engineering Materials with Innovative Characteristics. Fiberglass Reinforcement (GFRP), as a new type of composite material, is breaking through the application limitations of traditional steel bars with its groundbreaking properties. Its core advantages are concentrated in the following six dimensions, providing high-performance solutions for modern engineering.

1. Lightweight and high-strength, breaking through the bearing limit

The density of fiberglass reinforcement is only 1/4 of that of steel bars (1.5-1.9g/cm ⊃3;), yet it achieves a tensile strength that exceeds that of steel bars of the same specification by more than 20%. This "lightweight and high-strength" characteristic significantly reduces the self weight of the structure and reduces the bearing pressure of the foundation. In bridge engineering, the use of fiberglass reinforcement can reduce the weight of the main beam by 30% and increase its load-bearing capacity by 15%, achieving a dual breakthrough in economy and safety.

2. Corrosion resistant king, conquering industry's stubborn problems

Glass fiber reinforcement exhibits excellent durability in extreme environments such as chloride ion erosion and acid-base corrosion. Actual test data shows that its corrosion rate in seawater environment is only 1/200 of that of steel bars, and its service life in chemical pollution areas exceeds 50 years. After the application of a certain cross sea bridge project, maintenance costs have been reduced by 85%, completely solving the industry problem of traditional steel reinforcement rusting, swelling, and cracking.

3. Electromagnetic insulation, opening up special application scenarios

As a non-magnetic material, glass fiber reinforcement can be used in electromagnetic sensitive areas such as medical MRI rooms and high-voltage substations without demagnetization treatment. In the expansion project of a certain hospital, the use of this material reduced the interference rate of imaging equipment from 37% to 0.8%, ensuring the precise operation of medical equipment and opening up a new material standard in the field of biomedical construction.

4. Construction Revolution, Efficiency Increased by 40%

Non metallic tensioning straps are used for on-site binding, which increases installation speed by 40% compared to traditional welding processes. The customizable production features support the demand for irregular structures. In the application of Guangzhou Metro project, the prefabricated arc-shaped reinforcement can shorten the tunnel support period by 22 days and reduce labor costs by 35%.

5. Safety upgrade, dual protection of flame retardant and anti-static

The material has B1 level flame retardant performance, with an oxygen index of 38%, and no molten droplets are produced during combustion. In the protection engineering of oil storage tank areas, this feature reduces the risk of fire spread by 90%. At the same time, anti-static treatment technology avoids the generation of construction sparks and meets safety regulations for dust explosion hazardous areas.

6. Whole cycle cost optimization, significantly improving ROI

Although the unit price is 20% higher than that of steel bars, the full lifecycle cost analysis shows that in the sewage treatment plant project, the comprehensive cost is reduced by 42% over a 30-year period. This is due to the maintenance free feature, improved construction efficiency, and extended structural lifespan, which has enabled the return on investment to exceed the industry average.

7. Intrinsic Fire Protection: Redefining the "Safety Gene" of FRP Reinforcement

Advantages of Oxygen Index: The oxygen index reaches 38% (compared to only 26% for ordinary FRP bars), making it difficult to self ignite in air.

Fire extinguishing property: The flame extinguishes automatically within 3 seconds after removal, without any molten droplets, avoiding the risk of secondary fire.

Application scenario: In high-risk areas such as petrochemical storage tank areas and subway tunnels, it can replace traditional flammable materials and construct "fire isolation zones".

8. High temperature resistance and thermal shock resistance: a breakthrough from "softening" to "combining rigidity and flexibility"

Hot deformation temperature: up to 280 ℃ (ordinary FRP bars only have 180 ℃), and can withstand short-term flame impact at 1400 ℃.

Thermal shock resistance: After 100 cycles of cold and hot cycling from -40 ℃ to 150 ℃, the strength retention rate still reaches 92%.

Case comparison: After being used in a pipeline support project in a chemical industrial park, the structure remained intact in a fire, avoiding secondary disasters and directly reducing losses by over ten million yuan.

9. Corrosion resistance and durability: an upgrade from "short-term protection" to "long-term immunity"

Acid and alkali resistance: In a corrosive environment with a pH value of 2-12, the strength retention rate is ≥ 95%.

UV resistance: The surface is coated with fluorocarbon coating, which can be used outdoors for 50 years without aging or cracking.

Economic comparison: The total lifecycle cost is only 70% of traditional FRP reinforcement, and maintenance costs are approaching zero.

10. Lightweight and easy to construct: the transformation from "bulky" to "efficient"

Density advantage: Only 1/5 of steel, significantly reducing transportation and installation costs.

Cutting and Connection: Supports on-site manual cutting and comes with specialized connectors, increasing construction efficiency by 40%.

Design flexibility: Customizable curved bars with a bending radius ≥ 1.5m to meet the requirements of irregular structures.

3、 The engineering value brought by FM certification: from compliance to added value

1. Optimization of insurance costs

Projects certified by FM can receive insurance company rate discounts, with comprehensive premiums reduced by 15% -25%.

Feedback from a data center project: "After using Sende FM certified products, the annual insurance cost has decreased by 800000 yuan. ”

2. Market access advantages

Directly benchmarking against the North American NFPA 251 Fire Resistance Standard for Building Components, seamlessly connecting with high-end markets such as the United States and Canada.

Case study of a multinational engineering group: "After the product passed FM certification, it won the bid for the California high-speed rail project in the United States, with a contract amount exceeding 200 million yuan. ”

3. Social responsibility and brand premium

Compliant with LEED v4.1 fire safety bonus points, helping the project obtain green building certification.

After the use of a commercial complex, the owner's brand reputation increased by 30%, and the rental premium reached 8%.

4、 Sende Services: Full chain support from authentication to implementation

Certification file package

Provide complete FM certification reports, test data, and compliance statements to simplify the customer approval process.

Technical training system

Special training on "FRP Reinforcement Fire Safety Application Technology" has been conducted for design institutes and fire departments, covering over 150 engineering teams.

Global supply chain assurance

Establishing warehouse centers in North America and the Middle East can achieve emergency supply within 48 hours.

5、 Conclusion: Choose FM certification and select 'fire immunity'

In the field of fire safety, prevention and control have always been the core propositions. Anhui Sende FM certified FRP reinforcement, based on the highest international fire safety standards, provides users with a "zero compromise" solution through innovative breakthroughs in material science. Whether it's a life passage through a fire scene or an industrial facility carrying heavy assets, this product is proving with data that true engineering safety is never a multiple-choice question, but a must-have question that can be achieved through technology.

6、 Application scenario expansion

From bridges in permafrost regions of the Qinghai Tibet Plateau to island and reef docks in the South China Sea, from nuclear power plant containment to 5G base station rooms, fiberglass reinforcement is expanding its application boundaries at an annual market growth rate of 23%. Its characteristic combination perfectly adapts to high demand fields such as ocean engineering, rail transit, and medical construction, becoming a key force in promoting the revolution of engineering materials.

Choosing fiberglass reinforcement is not only about choosing a new material, but also injecting innovative genes of lightweight, durability, and intelligence into engineering. This breakthrough in materials science is redefining the safety standards and efficiency boundaries of modern engineering.

Contact Sende immediately to obtain the FM certified product selection manual and engineering case collection, so that your project can build a "firewall" from the beginning!