In construction projects, choosing the right materials for reinforcement and stabilization is crucial. One key material that plays a significant role in ensuring structural integrity is the anchor cable. Typically, anchor cables are used in construction to provide stability and support in various applications like slope stabilization, retaining walls, and tunnel linings. Traditionally, steel cables have been the go-to material, but Glass Fiber Anchor Cables (GFRP) are increasingly being used as an alternative due to their impressive performance and unique advantages.

This article will compare Glass Fiber Anchor Cables with Traditional Steel Cables, focusing on their cost-effectiveness over the life cycle of construction projects. We will evaluate the initial costs, installation requirements, maintenance needs, and long-term performance of both materials, to help you make the most informed choice for your next construction project.

1. The Importance of Choosing the Right Anchor Cable for Construction Projects

Role of Anchor Cables in Construction

Anchor cables are essential components in the structural integrity of many construction projects, including retaining walls, tunnels, and foundations. These cables are inserted into the soil or rock surrounding a structure and are used to anchor and stabilize it against various forces like soil movement, water pressure, and seismic activity.

Choosing the right type of anchor cable can make a significant difference in both the cost and performance of a project. The right anchor cable should provide adequate support, withstand environmental pressures, and require minimal maintenance over the life of the project.

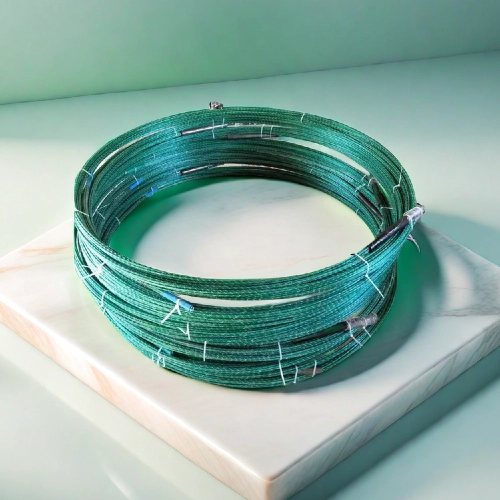

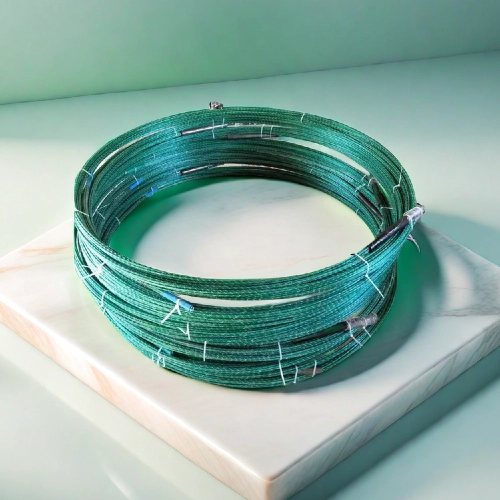

Introduction to Glass Fiber Anchor Cables

Glass Fiber Anchor Cables are composite materials made from glass fibers and polymer resins. Unlike traditional steel cables, GFRP cables are corrosion-resistant, lightweight, and offer excellent tensile strength. These properties make them ideal for use in harsh environments, such as areas with high moisture, chemical exposure, or seismic activity. Over the past few years, Glass Fiber Anchor Cables have gained traction as a viable and cost-effective alternative to steel cables.

Purpose of the Article

The goal of this article is to explore the cost-effectiveness of Glass Fiber Anchor Cables compared to Traditional Steel Cables. By comparing their initial material cost, installation expenses, maintenance requirements, and long-term durability, we will provide a comprehensive view of which material offers better value for construction projects.

2. Overview of Glass Fiber Anchor Cables

Material Composition

Glass Fiber Anchor Cables are made from a combination of glass fibers and polymer resins. The glass fibers provide high tensile strength, while the resin bonds the fibers and offers additional resistance to environmental factors such as chemicals and moisture. These cables are lightweight, durable, and do not rust, unlike steel cables, which makes them particularly suitable for use in demanding environments.

Properties of Glass Fiber Anchor Cables

Glass Fiber Anchor Cables offer several distinct advantages over traditional steel cables, including:

Corrosion Resistance: GFRP Anchor Cables are immune to corrosion, which is a major issue with steel cables in moist or chemically aggressive environments.

Lightweight: These cables are significantly lighter than steel cables, which makes them easier to transport and install, reducing labor and equipment costs.

High Strength: Despite being lightweight, Glass Fiber Anchor Cables have excellent tensile strength, allowing them to provide the necessary support in construction applications.

Chemical Resistance: GFRP Cables are highly resistant to various chemicals, making them ideal for use in industrial or water treatment facilities.

Applications of Glass Fiber Anchor Cables

Glass Fiber Anchor Cables are used in various construction applications, including:

Slope Stabilization: Preventing landslides and soil erosion in hilly or mountainous regions.

Tunnel Reinforcement: Strengthening tunnel linings and preventing collapse.

Retaining Wall Support: Securing retaining walls against the pressures of surrounding soil or water.

Bridge Construction: Providing long-term stability for bridges exposed to environmental stress.

3. Overview of Traditional Steel Cables

Material Composition

Traditional Steel Cables are made from high-strength steel wire, which is coated with anti-corrosive materials (usually zinc or other coatings) to protect the cables from rust and degradation. Despite the coatings, steel cables are still vulnerable to corrosion over time, especially in damp or saline environments.

Properties of Steel Cables

Steel cables are known for their:

High Strength: Steel has superior tensile strength compared to most other materials, making it an excellent choice for heavy-duty applications.

Weight: Steel cables are much heavier than Glass Fiber Anchor Cables, which can increase transport and handling costs.

Corrosion Sensitivity: Steel is prone to rust and corrosion, particularly in environments with high moisture, salt, or chemical exposure.

Durability: Steel cables have a relatively long lifespan but require regular maintenance to prevent rust and degradation.

Applications of Steel Cables

Steel Cables have been used for decades in various construction applications such as:

Bridge Construction: Steel is used for suspension cables and other structural elements.

Tunnels and Mines: Steel cables are used for reinforcement and support in tunnels, mines, and underground structures.

High-Tension Applications: Steel cables are used in cable cars, cranes, and other high-tension applications where strength is paramount.

Drawbacks of Steel Cables

Corrosion: Over time, steel cables can rust, especially when exposed to moisture and salt, requiring frequent inspections and replacements.

Heavier: Steel is much heavier than Glass Fiber Anchor Cables, leading to higher transportation and labor costs during installation.

Maintenance: Steel cables require more maintenance and monitoring for signs of wear and tear, increasing the overall lifecycle cost.

4. Cost Comparison: Glass Fiber Anchor Cables vs. Steel Cables

Initial Material Cost

Glass Fiber Anchor Cables: Typically, GFRP cables have a higher initial cost due to the manufacturing process and the materials involved in their production. However, these costs are offset by their long-term benefits.

Steel Cables: Steel cables generally have a lower initial cost compared to GFRP cables, making them an attractive option for short-term projects or applications with limited budgets.

Installation Costs

Glass Fiber Anchor Cables: GFRP cables are lighter and easier to handle, reducing transportation costs and installation time. This results in lower labor costs and faster project completion.

Steel Cables: Due to the heavy weight of steel cables, they require more labor for handling and installation, which increases overall installation costs.

Maintenance and Lifecycle Costs

Glass Fiber Anchor Cables: Due to their corrosion resistance, GFRP cables require minimal maintenance over their lifetime. They are more durable and do not need frequent replacements, which significantly reduces long-term costs.

Steel Cables: Steel cables are prone to rusting, especially in harsh environmental conditions. This requires regular inspections, maintenance, and occasional replacements, which can increase the total lifecycle cost.

Overall Cost-Effectiveness

While GFRP cables may have a higher initial cost, they are more cost-effective over the life of the project due to their low maintenance, long lifespan, and ease of installation. In contrast, steel cables may seem cheaper upfront but incur higher long-term maintenance and replacement costs.

Table: Cost Comparison Between Glass Fiber Anchor Cables and Steel Cables

Criteria | Glass Fiber Anchor Cables | Steel Cables |

Initial Material Cost | Higher, due to composite manufacturing | Lower, made from traditional steel |

Weight | Lightweight, easy to handle | Heavy, requires more labor and equipment |

Installation Time | Faster installation due to light weight | Longer installation time due to weight |

Maintenance | Low maintenance, corrosion-resistant | High maintenance due to corrosion |

Durability | Longer lifespan, minimal wear and tear | Shorter lifespan, needs frequent inspection |

Total Lifecycle Cost | More cost-effective long-term | Higher overall costs due to maintenance |

5. Environmental and Durability Considerations

Corrosion Resistance

Glass Fiber Anchor Cables: One of the most significant advantages of GFRP cables is their resistance to corrosion. They perform well in moist, saline, and chemical-rich environments, making them ideal for projects exposed to these conditions.

Steel Cables: Steel cables, despite coatings, are still prone to rust and corrosion over time, particularly in environments with high humidity, salty air, or chemicals, leading to reduced performance and higher maintenance.

Weight and Handling

Glass Fiber Anchor Cables: The lightweight nature of GFRP cables makes them easier to transport, handle, and install, which reduces logistics costs and installation time.

Steel Cables: Steel cables are heavy, requiring more equipment, labor, and time for installation, increasing overall costs.

Sustainability

Glass Fiber Anchor Cables: Made from recyclable materials, GFRP cables are a more environmentally friendly option. They reduce waste over the lifespan of the project due to their longevity and minimal maintenance.

Steel Cables: While steel is recyclable, the energy consumption required for its production and the ongoing maintenance contributes to a higher environmental footprint compared to GFRP cables.

6. Conclusion

When choosing between Glass Fiber Anchor Cables and traditional Steel Cables, it’s essential to consider both the initial investment and long-term savings. Glass Fiber Anchor Cables provide superior corrosion resistance, reduced maintenance costs, and a longer lifespan, making them a more cost-effective option for construction projects over time.

While Steel Cables may have a lower upfront cost, their heavier weight, susceptibility to corrosion, and higher maintenance requirements make them less economical in the long run. For projects that demand lasting stability, minimal upkeep, and a reduced environmental footprint, Glass Fiber Anchor Cables offer the ideal solution.

At JIMEI CHEMICAL Co., Ltd., we specialize in providing high-quality Glass Fiber Anchor Cables designed for maximum performance and cost-efficiency. We invite you to contact us to learn more about how our Glass Fiber Anchor Cables can help ensure the long-term success of your construction projects. Let us assist you in making the best choice for durability, cost-effectiveness, and sustainability.

7. FAQ

What are Glass Fiber Anchor Cables?

Glass Fiber Anchor Cables are composite cables made from glass fibers and polymer resins, designed to provide reinforcement and stability in construction applications. They offer high tensile strength, corrosion resistance, and lightweight properties.

How do Glass Fiber Anchor Cables differ from traditional steel cables?

Glass Fiber Anchor Cables are lighter, corrosion-resistant, and require less maintenance than steel cables, making them more suitable for projects exposed to harsh environmental conditions.

Are Glass Fiber Anchor Cables more expensive than steel cables?

While Glass Fiber Anchor Cables may have a higher initial cost, they are more cost-effective in the long term due to their durability, reduced maintenance, and longer lifespan.

What are the benefits of using Glass Fiber Anchor Cables?

Glass Fiber Anchor Cables offer benefits such as corrosion resistance, lower installation and maintenance costs, and a longer lifespan compared to traditional steel cables.

Can Glass Fiber Anchor Cables be used in all types of construction?

Yes, Glass Fiber Anchor Cables are suitable for various applications, including slope stabilization, tunnel reinforcement, and retaining walls, especially in harsh or corrosive environments.

How long do Glass Fiber Anchor Cables last?

Glass Fiber Anchor Cables have a long lifespan due to their corrosion resistance and durability, typically lasting much longer than traditional steel cables.

Are Glass Fiber Anchor Cables environmentally friendly?

Yes, Glass Fiber Anchor Cables are made from recyclable materials, and their long lifespan reduces the need for frequent replacements, making them an environmentally friendly choice.