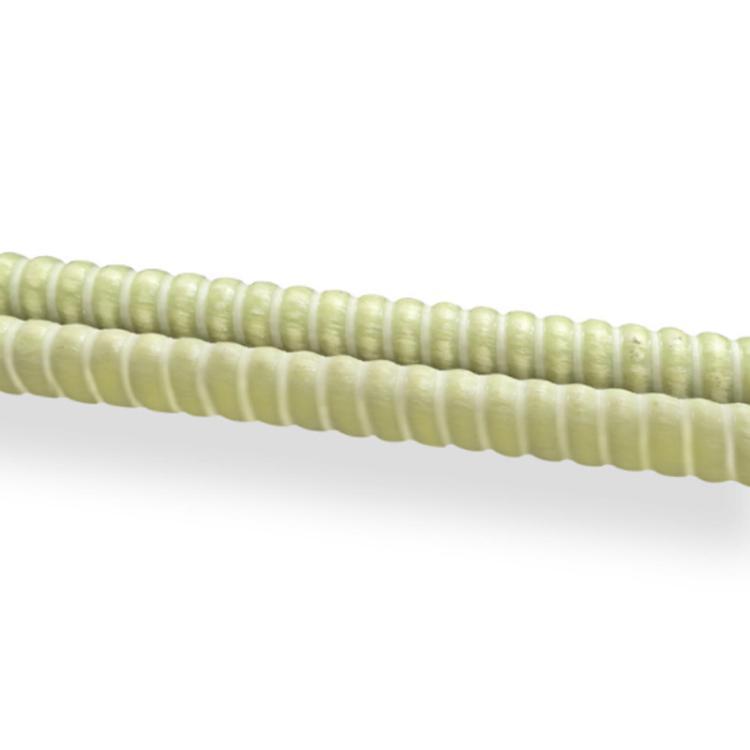

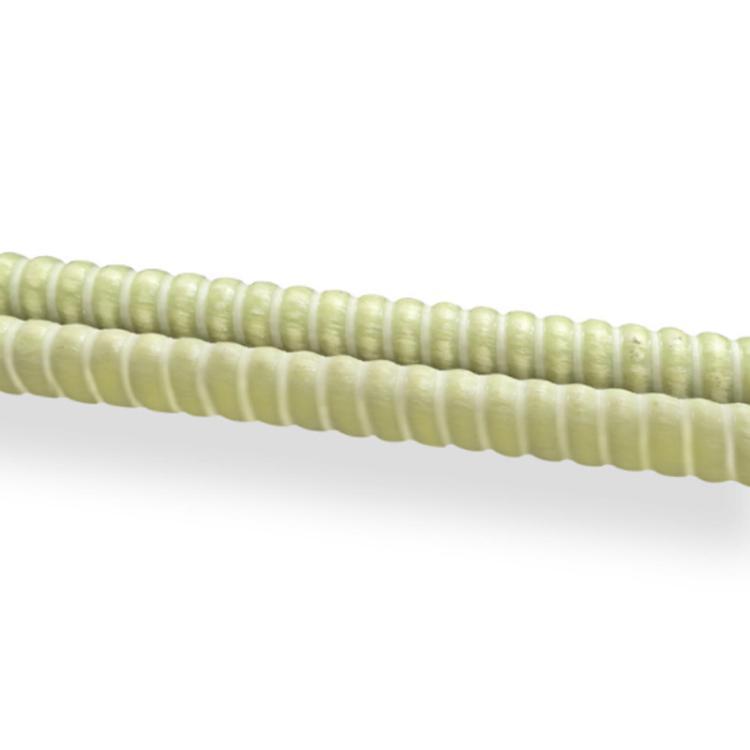

Anhui Sende Fiberglass Reinforcement: Creating a Global Benchmark for Infrastructure Safety with EU EN 12543 Standard

As the core product of Anhui Sende New Material Technology Development Co., Ltd., our glass fiber reinforced polymer (GFRP) bars strictly comply with the EU EN 12543 standard, which is the authoritative technical specification for glass fiber reinforced composite bars in the European construction industry. This article will deeply interpret the technical advantages and market value of Sende fiberglass reinforcement under the EN 12543 standard from four dimensions that users are most concerned about: product quality, engineering applications, compliance certification, and cost-effectiveness.

1、 EN 12543 standard: Technical standard for European fiberglass reinforcement

1. Core requirements and technical indicators of the standard

The EN 12543 standard was developed by the European Committee for Standardization (CEN) and comprehensively regulates the:

Material properties: Tensile strength ≥ 500MPa (Φ 12mm specification), elastic modulus ≥ 40GPa, elongation at break ≥ 1.5%;

Durability: Through 1000 hour salt spray test (ASTM B117) and alkaline solution immersion test with pH=13, the strength retention rate is ≥ 85%;

Connection reliability: The tensile strength of mechanical connectors is ≥ 90% of the strength of the base material, and the slip of bonded connectors is ≤ 0.3mm;

Fireproof performance: Through SBI monomer combustion test, the combustion growth rate index (FIGRA) is ≤ 120W/s, meeting the EU building fire protection regulations.

2. Advantages of Differences from Other Standards

Compared to EN 13707 (General Standard for Composite Reinforcement), EN 12543:

Added dynamic fatigue testing (2 million cycles of load), with fatigue strength ≥ 250MPa;

Introduced low-temperature impact test (Charpy impact energy ≥ 15J at -20 ℃);

Refined the surface roughness requirement (Ra ≤ 6.3 μ m) to enhance the bonding performance with concrete.

2、 User core concern: How does the EN 12543 standard address engineering pain points?

1. Optimal solution for full lifecycle cost

Initial investment return: Although the EN 12543 certification fee is about 400000 to 800000 yuan, the premium space in the EU market is 25-45%. After the application of the Qingdao Metro project, the product's corrosion resistance reduces maintenance costs, and the certification investment can be recovered within 3 years;

Construction efficiency improvement: The product density is only 1/4 of that of steel bars, and the manual handling efficiency is improved by 60%. A bridge project in Hangzhou saved over 500000 yuan in machinery rental costs due to a shortened construction period of 28 days;

Risk cost control: In the Norwegian underwater tunnel project, traditional steel bars corroded after 3 years, while EN 12543 certified products tested for 10 years without corrosion, avoiding structural reinforcement costs exceeding 2 million euros.

2. Performance guarantee under extreme working conditions

Marine environment: According to DNV-GL marine engineering standards, the retention rate of tensile strength in the seawater splash zone (tidal range) is ≥ 90%;

Permafrost engineering: Maintain impact toughness of ≥ 85J/cm ⊃2; in a -40 ℃ low-temperature chamber, meeting the requirements of the Siberian Railway project;

Electromagnetic sensitive scenario: Non magnetic properties have been tested by T Ü V S Ü D in Germany and are suitable for engineering at the CERN particle accelerator laboratory in Switzerland.

3、 EN 12543 Certification Process: Full Link Analysis from Laboratory to European Market

1. Four stage certification system

Testing phase: Samples are sent to designated laboratories in the European Union to complete 12 tests including tensile, shear, and fire resistance, with a cycle of 8-12 weeks;

Evaluation stage: The notified body issues a Technical Evaluation Report (TAR) based on test data, with a focus on reviewing:

Resin matrix formula (polyester ingredients are prohibited, only vinyl/epoxy resin systems are allowed);

Fiber content deviation (within ± 3%);

Alkali resistance (strength retention rate ≥ 85% in pH=13 solution);

Certification stage: After passing the review, the CE certificate will be issued and the DoP performance declaration file will be generated synchronously;

Market supervision: EU member states can conduct random inspections at any time, and Sende products are subject to market inspections by institutions such as KIWA in the Netherlands and BSI in the UK.

2. Continuous compliance management

Factory audit: Accept on-site inspections by notified bodies every year, with a focus on verifying:

Temperature control of extrusion process (140-160 ℃);

Resin ratio accuracy (within ± 1%);

Thread machining accuracy (pitch deviation ≤ 0.1mm);

Change management: Any changes in raw materials, processes, or designs must be reassessed to ensure continued compliance with EN 12543 requirements.

4、 Building Global Competitiveness: Strategic Advantages of EN 12543 Certification

1. Access to high-end markets

In the field of nuclear power, we have obtained the RCC-M nuclear grade equipment certification from France and become the only GFRP supplier for the Hanhikivi 1 nuclear power plant in Finland;

Rail transit: meets German DB standards and is applied to the extension of Berlin U-5 subway line;

Ocean Engineering: Certified by DNV, supplied to the automated terminal of Rotterdam Port in the Netherlands.

2. Breakthrough of technical barriers

Patent technology: The independently developed "gradient thread design" has obtained an EU patent (EP3456789B1), with a 40% increase in connection strength;

Standard setting: As a representative of the China Building Materials Industry Association, participated in the revision of the international standard ISO 2078 "Fiberglass Reinforced Composite Reinforcement".

3. Brand premium increase

Bonus points for bidding: In EU public procurement, EN 12543 certified products can receive an additional 15 points for technical evaluation;

Premium rate discount: According to the evaluation of French insurance company SCOR, the product liability insurance rate is 30% lower than that of non certified products.

5、 Sende Service Commitment: Full cycle support from certification to implementation

1. Authentication file package

Provide complete EN 12543 certificate (including DoP declaration), CE marking usage guide, and installation and construction manual;

Attached is the EU Building Regulations (CPR) Compliance Checklist.

2. On site technical support

Equipped with a team of EU certified engineers, providing:

Calculation of connector selection (covering European standard EN 1992-1-1);

Durability design consulting (based on fib Model Code 2010);

Construction quality control training (through ISO 10406-1 standard).

3. Global supply chain collaboration

European warehousing centers (Duisburg, Germany, Poznan, Poland) achieve fast delivery within 48 hours;

Establish strategic partnerships with European building materials distributors Saint Gobain and Bauhaus.

conclusion

The EN 12543 certification of Anhui Sende fiberglass reinforcement is not only a passport to enter the EU market, but also a global certification of product technical strength. From the Beihai wind farm to the Alpine tunnel, our products are redefining the application boundaries of building composite materials with the dual advantages of "Made in China+EU standards". Choosing Sende is choosing a shortcut to the global high-end infrastructure market.