Introduction

Saltwater environments pose one of the greatest challenges for construction materials. Traditional steel rebar rapidly corrodes, compromising structural integrity. So, how can we extend the lifespan of infrastructure in these harsh conditions?

In this article, we will explore the lifespan of fiberglass rebar in saltwater environments. You will learn how fiberglass rebar outperforms steel rebar, offering a longer-lasting solution for marine and coastal projects.

By understanding its benefits, you'll discover why fiberglass rebar is a smart choice for long-term durability and reduced maintenance in saltwater applications.

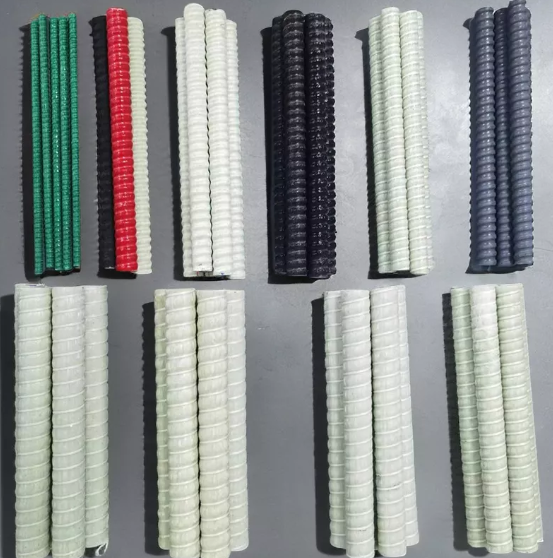

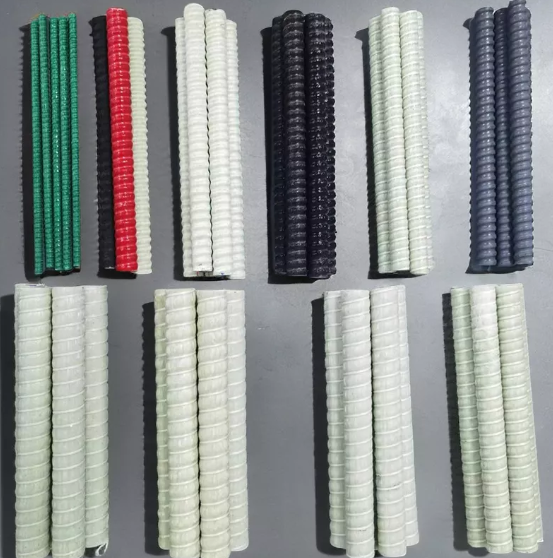

Basic Characteristics of Fiberglass Rebar

What Is Fiberglass Rebar and How It Works

Fiberglass rebar is a composite material made by embedding high-strength glass fibers within a polymer resin, typically either epoxy or vinyl ester. The combination of glass fibers and resin results in a material that is not only strong and durable but also lightweight. The glass fibers provide tensile strength, while the polymer resin binds the fibers and adds additional strength and flexibility, ensuring the material is robust and can handle various stress factors.

The key difference between fiberglass rebar and traditional steel rebar lies in the material's inherent resistance to corrosion. Steel, being a metal, is prone to rust when exposed to moisture, salt, and chemicals, especially in marine or coastal environments. Fiberglass rebar, on the other hand, is completely non-corrosive, which makes it particularly suitable for projects where corrosion could lead to structural failure or increased maintenance costs.

Why Fiberglass Rebar Resists Saltwater Corrosion

One of the most significant advantages of fiberglass rebar over steel is its resistance to corrosion, particularly in saltwater environments. Saltwater is known for rapidly accelerating the corrosion of metals, especially steel, which weakens over time as it rusts and loses its structural integrity. However, fiberglass rebar is designed to resist these corrosive effects entirely. The polymer matrix that surrounds the glass fibers acts as a barrier, preventing water and salts from penetrating and affecting the fibers inside.

Fiberglass rebar’s ability to withstand saltwater exposure makes it an excellent choice for marine and coastal construction projects, such as piers, seawalls, and docks. In these environments, where steel rebar would corrode quickly, fiberglass rebar ensures the longevity of the structure, maintaining its integrity for decades and reducing the need for frequent repairs.

| Property | Fiberglass Rebar | Steel Rebar |

| Corrosion Resistance | Highly resistant to corrosion | Prone to rust and corrosion in saltwater |

| Lifespan | Over 100 years in saltwater | 20-30 years before corrosion issues |

| Weight | Lightweight (1/4th of steel weight) | Heavy |

| Maintenance Needs | Low maintenance | High maintenance due to rust |

| Cost | Higher initial cost | Lower initial cost |

Lifespan of Fiberglass Rebar in Saltwater Environments

Environmental Factors Impacting Fiberglass Rebar's Lifespan

While fiberglass rebar is highly resistant to corrosion, it is still susceptible to other environmental stressors that may affect its performance. Some of the key environmental factors that influence its lifespan include:

UV radiation: Prolonged exposure to direct sunlight can degrade the polymer resin, which might affect the material’s mechanical properties. However, fiberglass rebar is often treated with UV inhibitors, which significantly reduce this effect.

Chemical exposure: In certain industrial environments, fiberglass rebar may be exposed to chemicals that can potentially attack the resin or the fibers. Nevertheless, fiberglass rebar is more resistant to chemical exposure than steel rebar, making it ideal for chemical plants or other similar environments.

High temperatures: Extreme temperatures can weaken the polymer resin, potentially reducing the mechanical strength of the rebar. However, fiberglass rebar is designed to withstand high temperatures better than traditional steel rebar, making it suitable for use in hot climates or areas where elevated temperatures are common.

Despite these factors, fiberglass rebar generally performs well in most harsh environments and can last for several decades, especially when treated with proper coatings and installed in a way that protects it from excessive exposure.

| Environmental Factor | Impact on Fiberglass Rebar | Solutions/Prevention |

| UV Radiation | Can degrade polymer resin | UV inhibitors, protective coatings |

| Chemical Exposure | Can affect the polymer or fibers | Resistant resin for specific chemicals |

| High Temperatures | May soften the polymer matrix | High-temperature resistant resins |

| Saltwater Exposure | No corrosion, stays unaffected by saltwater | Ensures longevity in marine environments |

How Fiberglass Rebar Performs in Saltwater Over Time

Fiberglass rebar has been shown to maintain its structural integrity over long periods of exposure to saltwater, making it an ideal material for projects in coastal or marine environments. Unlike steel rebar, which begins to corrode and deteriorate in saltwater after just a few years, fiberglass rebar remains unaffected by the salt, moisture, and chemicals that typically degrade metals.

In fact, fiberglass rebar is designed to provide exceptional long-term performance, with a lifespan that often exceeds 100 years in saltwater conditions when properly installed. This makes it a highly cost-effective solution for infrastructure projects that require long-term durability and minimal maintenance. The ability of fiberglass rebar to resist the damaging effects of saltwater allows for the construction of more sustainable structures with fewer repairs or replacements required over time.

Maintenance and Replacement: How Long Does Fiberglass Rebar Last?

One of the most significant benefits of fiberglass rebar is its low maintenance requirements. Unlike traditional steel rebar, which requires regular inspections and treatments to prevent rust, fiberglass rebar remains corrosion-free throughout its lifespan. This reduces the need for frequent repairs, inspections, and replacement, making it an excellent option for reducing long-term maintenance costs.

In terms of replacement cycles, fiberglass rebar can last much longer than steel. Steel rebar may need to be replaced every 20 to 30 years in marine environments due to corrosion, but fiberglass rebar can last more than 100 years without the need for replacement. This extended lifespan makes fiberglass rebar a highly cost-effective investment in infrastructure projects, especially those that will be exposed to saltwater or other corrosive environments.

| Material | Lifespan in Saltwater Environments | Lifespan in General Construction |

| Fiberglass Rebar | 100+ years | 100+ years |

| Steel Rebar | 20-30 years | 50 years (subject to conditions) |

Advantages and Challenges of Using Fiberglass Rebar

Key Benefits of Fiberglass Rebar in Harsh Environments

Fiberglass rebar offers several advantages in environments where traditional steel rebar would fail. These benefits include:

Corrosion resistance: Fiberglass rebar’s ability to resist corrosion in saltwater environments makes it ideal for marine and coastal construction projects, where steel would rust quickly.

Long lifespan: The durability of fiberglass rebar ensures that structures reinforced with it will require fewer repairs and have a significantly longer lifespan compared to those reinforced with steel.

Lightweight: Fiberglass rebar is much lighter than steel, which makes it easier to handle, transport, and install. This reduces labor costs and installation time, contributing to overall cost savings.

Non-conductive and non-magnetic: In specific projects where electromagnetic interference needs to be minimized, such as in hospitals or research labs, fiberglass rebar is an ideal choice. It does not conduct electricity or generate magnetic fields, unlike steel.

Challenges in Adopting Fiberglass Rebar

Despite its many benefits, there are some challenges in adopting fiberglass rebar on a large scale:

Higher initial investment: Fiberglass rebar tends to be more expensive than traditional steel rebar upfront, which can be a barrier for some construction projects. However, the long-term cost savings due to reduced maintenance and replacement needs often outweigh this initial investment.

Special installation requirements: Fiberglass rebar requires specific tools for cutting, tying, and placing. Traditional steel rebar tools may damage the fiberglass rebar, affecting its performance. Specialized equipment and skilled labor are required to handle and install fiberglass rebar effectively.

Applications of Fiberglass Rebar in Construction

Marine and Coastal Infrastructure Projects

Fiberglass rebar is increasingly used in marine and coastal infrastructure projects, where exposure to saltwater is a constant concern. Structures such as seawalls, docks, piers, and bridges are frequently subjected to saltwater, which accelerates the corrosion of steel rebar. By using fiberglass rebar in these applications, the need for frequent maintenance is reduced, and the longevity of the structure is extended.

For instance, in coastal areas where steel would corrode within a few years, fiberglass rebar can provide decades of protection, ensuring that infrastructure remains strong and reliable for many years.

Fiberglass Rebar in Industrial and Residential Projects

In addition to marine applications, fiberglass rebar is also gaining traction in other sectors, including industrial and residential construction. In chemical plants, where the environment is often exposed to corrosive substances, fiberglass rebar provides superior durability compared to steel. Additionally, in residential construction, fiberglass rebar can be used in foundations, driveways, and swimming pools, offering a lightweight, corrosion-resistant alternative to traditional steel.

Future Outlook for Fiberglass Rebar in Construction

As the construction industry continues to focus on sustainability and reducing the environmental impact of materials, the demand for fiberglass rebar is expected to grow. Its durability, longevity, and low maintenance requirements position it as a preferred choice for engineers and construction professionals who are looking for more sustainable building materials.

The trend towards green building practices, coupled with the increasing need for infrastructure projects that can withstand harsh environments, will drive further adoption of fiberglass rebar in the coming years. This material’s exceptional performance in saltwater and other aggressive environments makes it a valuable asset for future construction projects.

Conclusion

Fiberglass rebar is an excellent choice for construction projects in saltwater environments. Its corrosion resistance, lightweight design, and extended lifespan make it a superior alternative to steel rebar. Although the initial investment may be higher, the long-term savings in maintenance and replacements make it a cost-effective solution. Anhui SenDe New Materials Technology Development Co., Ltd. provides high-quality fiberglass rebar, offering significant value by ensuring durable, low-maintenance infrastructure for coastal and marine projects.

FAQ

Q: What is Fiberglass Rebar and why is it used in saltwater environments?

A: Fiberglass rebar is a corrosion-resistant reinforcement material made of glass fibers and polymer resin. It is ideal for saltwater environments because it doesn’t rust like steel rebar, ensuring long-lasting structural integrity.

Q: How long does Fiberglass Rebar last in saltwater?

A: Fiberglass rebar can last over 100 years in saltwater environments, significantly longer than steel, which deteriorates within 20-30 years due to corrosion.

Q: What are the advantages of using Fiberglass Rebar in marine projects?

A: Fiberglass rebar resists corrosion, reducing maintenance costs. It’s lightweight, durable, and ideal for projects exposed to harsh saltwater conditions.

Q: How does Fiberglass Rebar compare to steel rebar in saltwater?

A: Unlike steel, which rusts quickly in saltwater, Fiberglass rebar offers superior corrosion resistance, resulting in longer lifespan and reduced maintenance needs in marine environments.

Q: Is Fiberglass Rebar more expensive than steel rebar?

A: Yes, Fiberglass rebar has a higher initial cost than steel. However, the long-term savings on repairs and replacements make it a cost-effective choice for projects in saltwater environments.

Q: Can Fiberglass Rebar be used in all types of construction?

A: While Fiberglass Rebar is ideal for coastal and marine projects, it’s also used in industrial and residential construction where corrosion resistance is needed.