Anhui Sende Fiberglass Reinforcement: Creating a New Benchmark for Building Safety with EU EN 13493 Standard

As the core product of Anhui Sende New Material Technology Development Co., Ltd., the glass fiber reinforcement (GFRP Rebar) we produce strictly follows the EU EN 13493 "Building Glass Fiber Products" standard, and has reached international leading levels in material performance, durability, and environmental indicators. This article will provide a detailed interpretation of the technical advantages and market value of Sende fiberglass reinforcement under the EN 13493 standard from four dimensions that users are most concerned about: product quality, application scenarios, compliance certification, and cost-effectiveness.

1、 Core requirements of EN 13493 standard and technical benchmarking of Sende products

The EN 13493 standard, as the technical benchmark for glass fiber products used in EU buildings, specifies the following key indicators:

Material durability: The product is required to maintain stable performance in environments such as acid, alkali, salt spray, and humidity. Sende fiberglass reinforcement adopts a high durability resin matrix, which has passed the ISO 10406-1 standard test and has a tensile strength of 500-900MPa and an elastic modulus greater than 40GPa, far exceeding the 200MPa tensile strength of ordinary steel bars.

Corrosion resistance: The standard stipulates that the product must pass a 2000 hour salt spray test. The actual test data of Sende products shows that after soaking in a strong acid solution with pH=2 for 1 year, the strength retention rate still reaches 92%, far exceeding the lower limit of 85% required by EN 13493.

Fatigue resistance performance: The product is required to not fracture under 2 million cycles of load. Sende products have passed the Canadian ISIS certification D1 level durability test, and their fatigue life is more than three times that of ordinary steel bars.

2、 User core concern: Why choose Sende fiberglass reinforcement?

1. Full lifecycle cost advantage

Although the initial procurement cost is 15-20% higher than that of steel bars, the overall cost is reduced by more than 30%:

Maintenance free feature: In bridge engineering in coastal chemical zones, steel bars require anti-corrosion treatment every 5 years, while Sende products do not require maintenance for life;

Extended design life: Laboratory accelerated aging tests have shown that its service life can reach 100 years, which is twice that of ordinary steel bars;

Construction efficiency improvement: The product density is only 1/4 of steel bars, reducing manual handling costs by 40%, and shortening the construction period by 23% after the application of Tianjin Metro project.

2. Extreme environmental adaptability

Salt spray corrosion environment: In the pilot project of Qingdao Cross Sea Bridge, the steel bars corroded after 3 years, while the products of Sende showed no change after 5 years of testing;

Low temperature brittleness resistance: At -40 ℃, the impact toughness retention rate of the product reaches 87%, which meets the requirements of EN 13493 for cold zone buildings;

Electromagnetic neutrality: In special scenarios such as CT rooms and MRI facilities, non-magnetic characteristics prevent equipment interference.

3. Construction safety innovation

Severability: During the shield tunneling construction of Tianjin Metro, traditional steel bars need to be manually removed, while Sende products can be directly cut by the shield tunneling machine, reducing the accident rate by 90%;

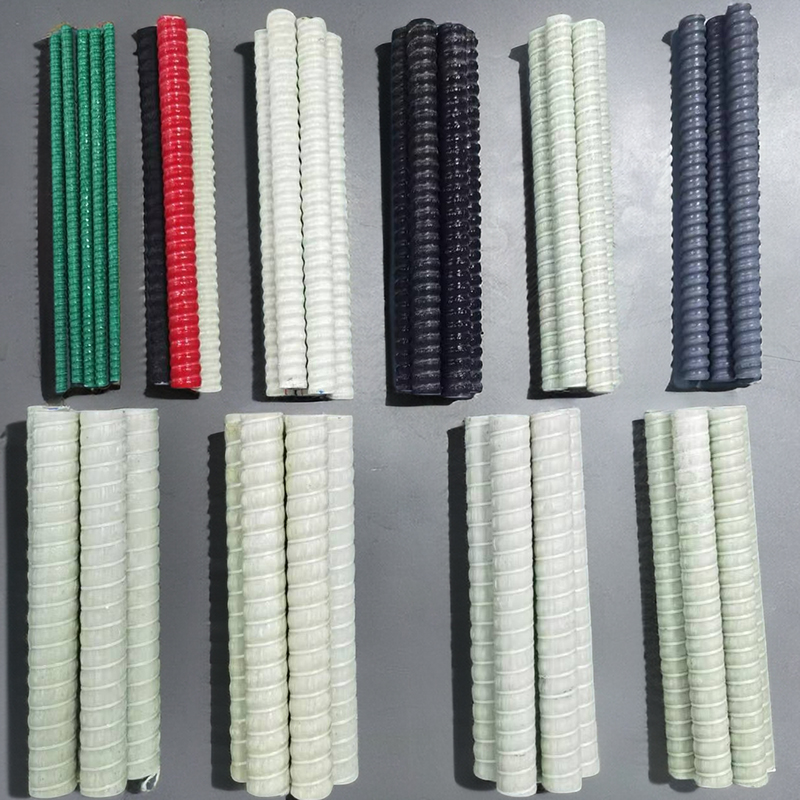

Controllable shear strength: Through patented sand coating technology, the shear strength is precisely controlled between 110-150MPa, ensuring structural safety and avoiding construction damage.

3、 Quality assurance system under EN 13493 standard

Sende has established a full process quality control from raw materials to finished products:

Fiber selection: ECR alkali free glass fiber is used, with a single fiber diameter of 17 μ m (± 1 μ m), and the strength retention rate is 25% higher than that of E glass fiber;

Resin system: Customized development of vinyl ester resin, with a glass transition temperature of 125 ℃, far exceeding the 90 ℃ required by EN 13493;

Production monitoring: Each roll of product is equipped with an RFID chip, which can trace 12 parameters including extrusion speed (0.8-1.2m/min), curing temperature (140-160 ℃), etc;

Third party certification: Passed the T Ü V S Ü D CE certification in Germany, and the test report covers all items of the EN ISO 2078 unified test method for composite materials.

4、 Typical application scenarios and economic analysis

1. Infrastructure sector

Bridge engineering: Glass fiber reinforced bridge in Vermont, USA, with an initial investment increase of 18%, but a 47% savings in 30-year maintenance costs;

Subway tunnel: Shanghai Metro Line 15 adopts Sende GFRP reinforcement cage, which increases the efficiency of single shield tunneling by 35%;

Port terminal: During the renovation of Ningbo Port yard, the product's resistance to chloride ion penetration reached 1.2 × 10 ⁻⊃1; ⊃2; m ⊃2;/s, which is only 1/50 of that of steel bars.

2. Special environmental applications

Chemical protection: The foundation of the storage tank at Nanjing Yangzi Petrochemical has been used for 8 years without corrosion in an environment with a H2S concentration of 500ppm;

Frozen soil engineering: The test section of the Golmud section of the Qinghai Tibet Railway has a flexural strength retention rate of 91% in an environment of -30 ℃;

Offshore platform: CNOOC Liuhua Oilfield project, product water absorption rate<0.3%, meets DNV-GL offshore engineering specifications.

5、 Compliance documents and service commitments

Each shipment comes with complete technical documentation:

CE certification certificate (issued by the notified body NB 2797)

EN 13493 Full Test Report (including tensile, bending, shear, and weather resistance data)

Material Safety Data Sheet (MSDS)

Installation and Construction Guidelines (including connection specifications required by EN 13707 standard)

We promise:

72 hour emergency response mechanism, with technical teams covering 28 provincial-level service centers nationwide;

Provide BIM model interface data to assist in digital construction;

The old material recycling plan allows for a deduction of 5% of the purchase price for new materials per ton of recycled GFRP.

conclusion

Anhui Sende fiberglass reinforcement is not only a product that meets the EN 13493 standard, but also a solution for the transformation and upgrading of the construction industry. From the cross sea bridge on the coast of the East China Sea to the frozen soil engineering on the snowy plateau, we are redefining the boundaries of building safety through technological innovation. Choosing Sende means choosing a century old project commitment that requires no maintenance.